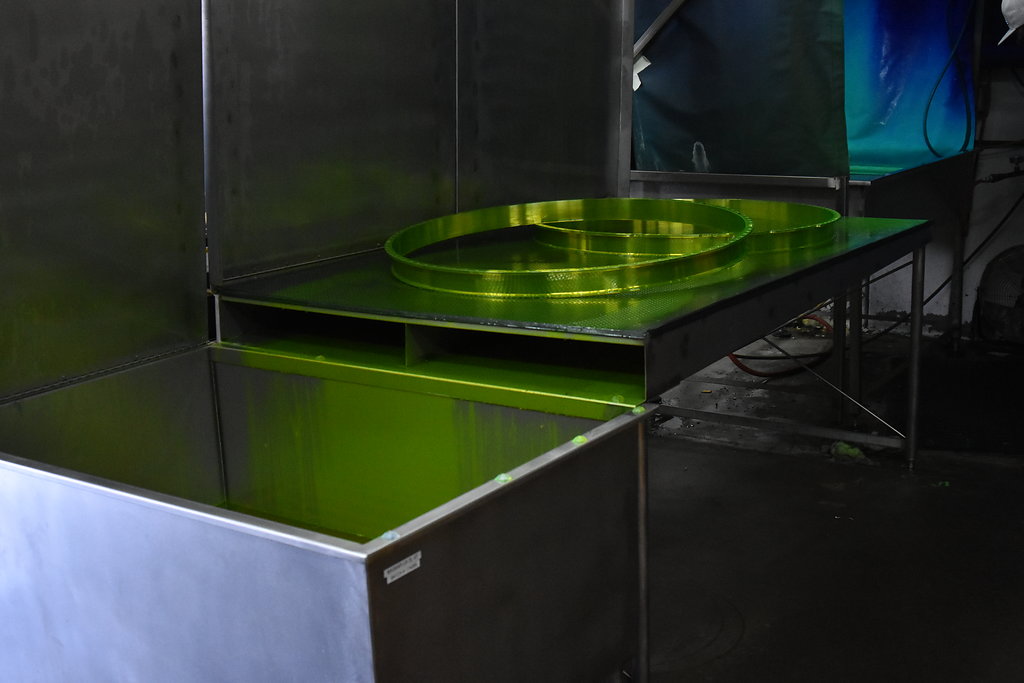

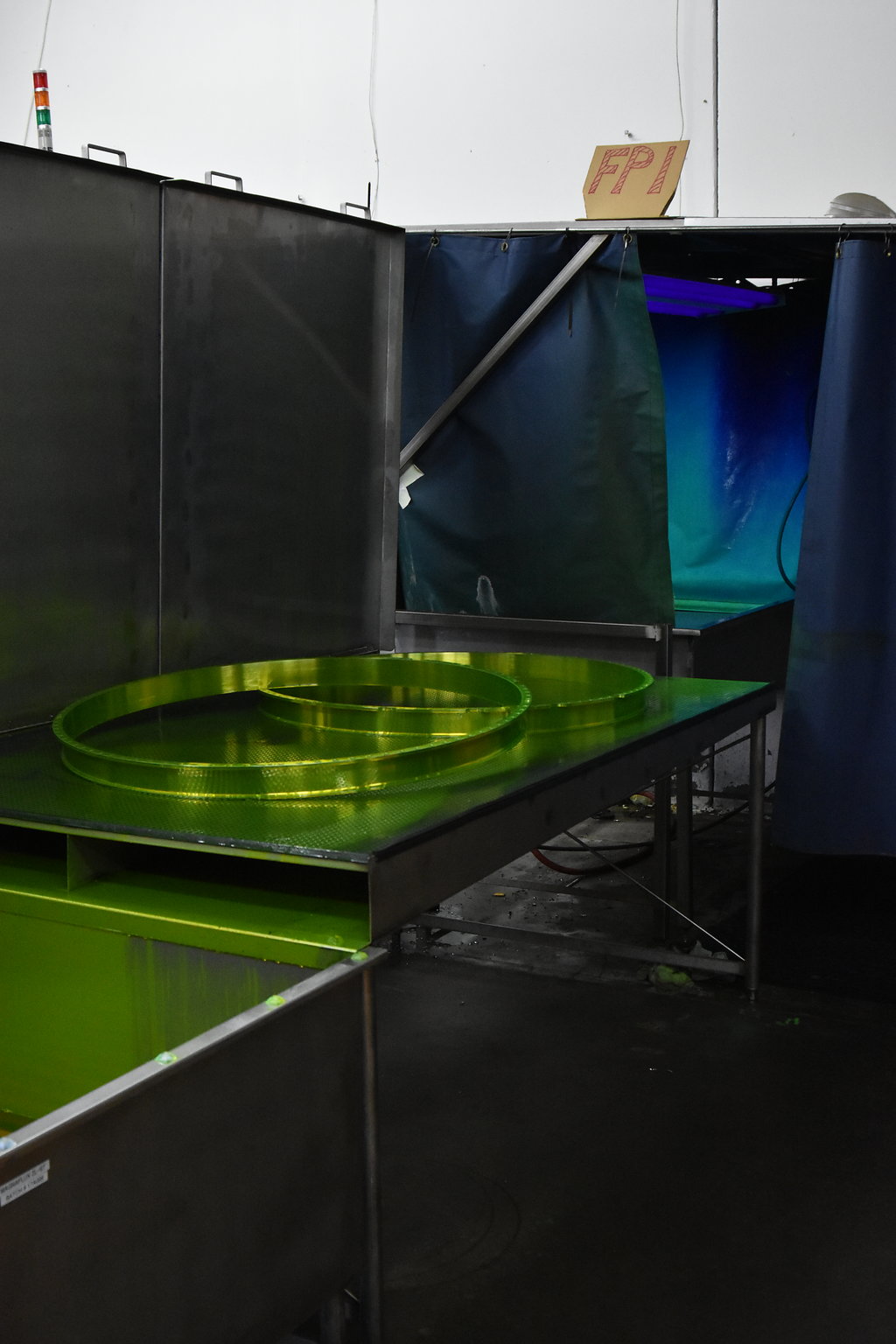

Fluorescent Penetrant Testing

Dye penetrant inspection (DPI), also called liquid penetrant inspection (LPI) or penetrant testing (PT), is a widely applied and low-cost inspection method used to locate surface-breaking defects in all non-porous materials (metals, plastics, or ceramics). At GMS we choose to use the Fluorescent Penetrant Inspection method (FPI) of LPI due to its incredibly high level of accuracy. There are many types of dye used in penetrant inspections. FPI operations use a dye much more sensitive to smaller flaws than the penetrants used in other DPI procedures. Here at GMS we use Magnaflux ZL67 Type 1 High Sensitivity Fluorescent Penetrant and Magnaflux ZP4B Method "A" Dry Powder Developer. With its brilliant yellow glow, caused by its reaction with ultraviolet radiation, FPI dye sharply contrasts with dark backgrounds. A vivid reference to even the most minute flaw is easily observed by a skilled FPI inspector.

Because of its sensitivity to such small defects, FPI is ideal for most metals which tend to have small, tight pores and smooth surfaces. Defects can vary but are typically tiny cracks caused by processes used to shape and form the metal. It is not unusual for a part to be inspected several times before it is considered finished and ready for shipping (an inspection often follows each significant forming operation). GMS Metal Works is NADCAP approved for FPI. We specialize in hard and exotic metals.

Below are just a few of the benefits of using Fluorescent Penetrant Inspection.

- Highly sensitive fluorescent penetrant is ideal for even the smallest imperfections

- Low cost and potentially high volume

- Our Technicians are extensively trained in FPI methods

- Learning that a defect exists prior to upstream processing, or use of the part in production, can save enormous amounts of money and reduce liability